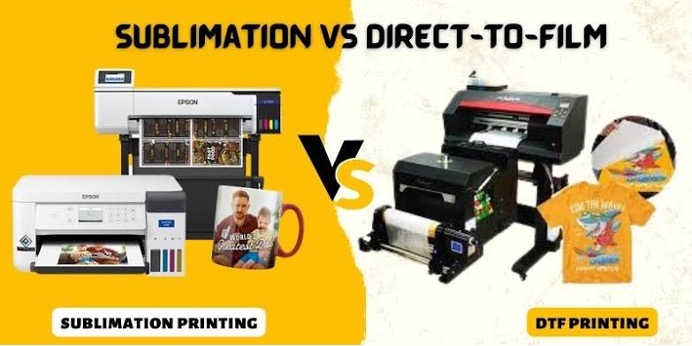

DTF printing and sublimation printing are two common heat-transfer printing techniques. Although they share some similarities, there are also significant differences between them. Specifically, DTF printing works on all types of fabrics. This printing technique produces vibrant colors and a layer with a tactile sensation. In contrast, sublimation printing only works on light-colored polyester fabrics. However, it offers photorealistic quality without the touch-feeling layer.

Understanding these differences is vital. It helps you to determine which printing method suits your business needs.

What is DTF Printing?

DTF printing is a simple and innovative printing method. It involves a DTF printer, shake powder machine, and heat press machine. To get started with this process, the DTF (Direct To Film) printer prints patterns onto DTF film. The heat press machine transfers This pattern to the desired fabrics.

This printing technique is highly efficient in transferring patterns onto various fabrics. It is particularly effective for small-scale printing on cotton, polyester, and nylon materials. The result is a realistic, high-quality image that is rich in color. Also, the result has excellent longevity without fading.

Are you a business owner looking to promote your brand on clothing and banners? DTF printing is the perfect solution for you.

Pros

- DTF printing works on all kinds of fabric.

- It is ideal for dark and light-colored materials.

- It delivers high-precision, clear, and stunning patterns.

Cons

- Colors in DTF printing are not as rich as in sublimation printing.

- The feel of the printed areas is not as soft as that of sublimation printing and may crack at any time.

- DTF printing only prints one item at a time.

What is Sublimation Printing?

Sublimation printing is another digital printing process. It uses vivid, full-color artwork to produce unique and stunning designs. This process involves using a sublimation printer to transfer patterns onto sublimation paper. The pattern is then heat-pressed onto clothing or polyester or polymer coatings items. This step requires the use of a heat press machine. This machine applies temperature and pressure to create a durable and vibrant print.

This printing technology is ideal for creating decorative clothing, logos, and banners. It is also perfect for personalizing small items. For example, pillows, plaques, and coffee cups can be easily sublimated. The process of sublimation printing utilizes the principles of sublimation. It transfers the dye directly onto the surface of solid objects. This transfer happens without the dye passing through the liquid phase. With the application of pressure, the dyes seep into the surface. This impact produces a vibrant and long-lasting print.

Pros

- Sublimation printing works on hard surfaces like mugs and plates.

- The result (printed fabric) is soft and breathable

- Unlimited print runs, making it fit for industrial use.

Cons

- Limited to polyester fabrics only.

- Unfit for dark-colored substrates.

What is the Difference Between DTF and Sublimation Printing? Key Differences Explained

● Application Material and Color

DTF printing is an excellent choice for printing on various fabrics. These options include knitting, textiles, nylon, non-woven fabrics, and almost all other fabrics. But, sublimation printing is only suitable for light-colored or white polyester fabrics. The brighter you need the color of the fabric print, the more polyester it should contain.

Unlike sublimation printing, DTF printers produce well-defined designs on light and dark-colored fabrics. Yet, sublimation printing is only suitable for printing on light-colored fabrics. Additionally, sublimation printing cannot produce the color white. This limitation makes designs with white elements challenging to print using this method.

● Workflow

The DTF printing involves the following steps:

- Refine the images using software.

- Print the image

- Use a shaker powder machine to cure the pattern

- Press the pattern on the fabric with the heat press machine for 10-15 seconds. Ensure the machine is set at 135~165℃.

- Peel off the transfer film

For sublimation printing, you start with designing the image. Then, you print the pattern on the chosen sublimation paper with no powder shaking. Next is to transfer the pattern to the clothing or other items using a heat press machine.

● Print Size

One of the main differences between these two is the print size. DTF printers have smaller platens compared to sublimation printers. Platens are the surfaces that imprint the image designs onto the substrate. In DTF printing, the platen size is 12″ x 15″, While sublimation printers have larger platens measuring 16″ x 20″.

If you want to create an all-over print design on a fabric, sublimation printing is the better option. Attempting to cover the cloth with a DTF printer would require multiple passes. That means it takes a lot of time to complete the entire print.

● Print Quality and Transfer Process

DTF and sublimation printing techniques transfer the design to the product using heat. But, they differ in their process. DTF printing uses an adhesive to transfer the image through transfer paper. Meanwhile, sublimation printing bonds the ink to fabric molecules. The process involves converting the ink from a solid to a gas immediately. It doesn’t need to pass through the liquid state.

Their transfer process is different. And this difference affects the quality and durability of the print. DTF printing offers better print quality. This perk is because the ink is directly applied to the product. And that produces a higher image resolution with more detailed prints.

On the other hand, sublimation printing embeds the ink into the fabric. That technique produces a subtle print but has longer-lasting colors. Sublimation prints will not fade, crack, or peel over time.

Sublimation printing is a more durable option. There’s zero risk of wear, tear, or fading through repeated washing and wearing. Yet, due to its lower resolution, you lose finer details in the design in the fabric’s print.

● Touch Feel

The transfer film used in DTF printing has a white ink layer on the back. This layer gives the printed fabrics a tangible texture. This texture is similar to the feeling of the image layer on a regular T-shirt.

On the other hand, sublimation printing involves the ink penetrating the fabric. Hence, you get a seamless blend between the image and the clothing. This result means there is no tangible texture to the print.

● Market

DTF printing is an incredibly versatile technique that works well on various fabrics. The possibilities for unique and eye-catching designs are endless. This technique delivers the best from cotton to polyester and blends. Even more impressive is the high-quality and exceptional detail that DTF printing produces.

Also, the prints have a soft feel on the fabric. This feel makes them perfect for intricate designs and outstanding photorealistic images. DTF printing is an excellent choice for producing high-quality prints. It is your go-to option for a one-of-a-kind t-shirt or a custom hoodie,

Sublimation printing is a remarkable technique for light-colored or white polyester materials. It is widely used in the world of sportswear. This printing technique mainly works for striking banners, flags, jerseys, and home textiles.

● Scale

Sublimation printing is the clear choice for companies that require large-scale garment printing. On the other hand, DTF printing is ideal for small print runs. For businesses with bulk orders, investing in sublimation printers is the way to go. However, if the demand is manageable, a DTF print will suffice.

● Cost

The cost of buying printed products using either of the methods is more or less the same. DTF printing might be cheaper since it doesn’t need transfer paper. But the total difference in cost isn’t significant. The prices will fluctuate depending on the kind of fabric you plan to print on. Other factors include the size of your order and the intricacy of your design.

Is DTF Better Than Sublimation?

Both DTF and sublimation printing have their unique features.

Generally, sublimation printing is the way to go if you want photorealistic prints. Hence, it is a top choice for bright-colored items like sportswear. But, DTF printing is ideal for producing vivid color printouts on all fabrics. It works for light- or dark-colored substrates, such as cotton t-shirts.

Are you still unsure about which printer to choose? Will your choice be the cost-effective DTF printer or the Sublimation printer? Consult experts for professional advice. With the right choice, you get excellent, gorgeous color printing outputs. And your printing business will exceed customers‘ expectations.

DTF vs Sublimation: Which is Right for You?

Choosing between DTF printing and sublimation printing can be challenging. The ideal choice will depend on your specific needs and budget. DTF printing might be the best option for you if you’re working with a tight budget and only need smaller runs of printed products. On the other hand, sublimation printing might be a better choice if you have more money to spend and require larger runs of printed products.

Therefore, it’s crucial to consider your business requirements carefully. The right printing method for your business depends on what you need, what your customer wants, and the industry you are in. Consider these before deciding on the best printing method for you.